Table Saw Blades

The table saw blade is the single most important accessory, so choosing wisely for diffent task makes a huge difference in the result. To empower decision-making, it's important to understand the foundational elements of table saw blade anatomy and familiarize oneself with diverse tooth configurations such as FTG, ATB, and TCG. In this session, we'll elucidate the significance of these terms and explore their impact on the cutting performance of your blade:

Terminology

Understanding table saw tooth terminology is the first step for selecting the right blade for your specific needs.

- Tooth Count:

- Grind:

- Hook Angle:

- Gullet:

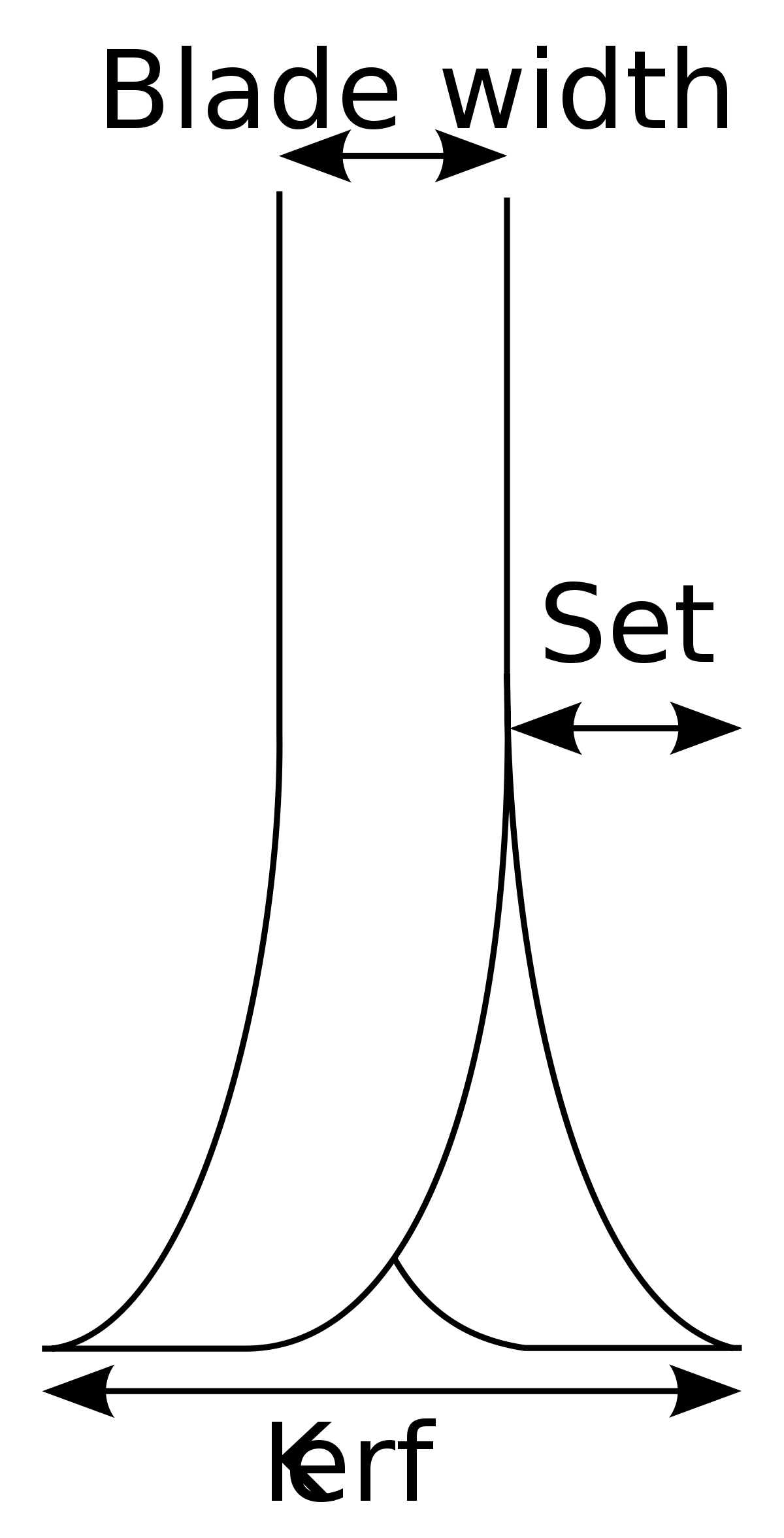

- Kerf:

- Kerf refers to the width of the slot cut by the table saw blade into the material being worked on.

- Determined by the thickness of the blade and the set of its teeth

- Thinner kerf blades require less power from your saw.

- Understanding kerf width is crucial for optimizing material usage and achieving desired dimensions in woodworking projects.

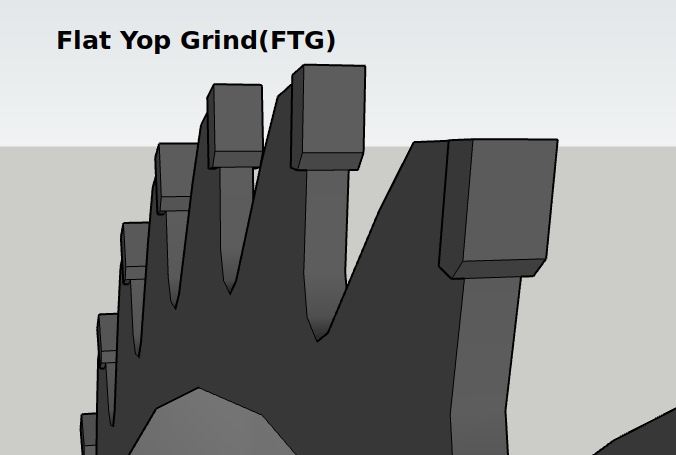

- Flat-Topped Ground (FTG)

- Teeth have square-shaped tops.

- Ideal for efficient cutting through materials, especially for rip cuts.

- Provides clean and fast cuts with minimal tearing and burns on wood.

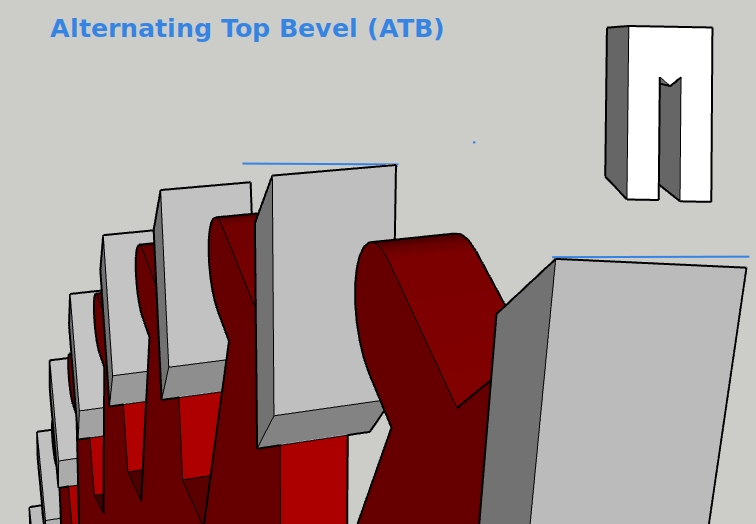

- Alternating Top Bevel (ATB)

- Teeth feature angled tops alternating between left and right bevels.

- Suitable for crosscuts and general purpose use.

- Offers smooth cuts across different types of wood grains.

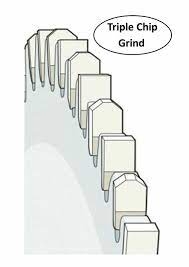

- Triple Chip Grind (TCG)

- Consists of a sequence of flat-topped teeth followed by chamfered teeth.

- Specifically designed for cutting hard and abrasive materials.

- Minimizes chipping and produces clean cuts in materials like laminate, MDF, and non-ferrous metals.

Impacts the fineness of the cut and feed rate. More teeth offer a cleaner cut but can slow down cutting speed.

The shape of the teeth, including FTG (Flat Top Grind), ATB (Alternate Top Bevel), and various combinations.

How aggressively the tooth interacts with the wood. Aggressive hook angles are ideal for rip cuts but can be more prone to kickback.

The space between teeth that traps sawdust and clears debris. Wider gullets improve waste removal in rip cuts.

Blade Types

These offer a balance between rip cuts (cutting along the grain) and crosscuts (cutting across the grain). A good starting point for general woodworking.

Designed for efficient rip cutting. They have fewer teeth with aggressive gullets for fast chip removal.

Ideal for smooth crosscuts in both solid wood and sheet goods. They have many fine teeth and a slightly different tooth geometry.

A versatile middle ground, offering decent rip and crosscut performance.

These exist for tasks like cutting melamine without chipping (blades with many small teeth), making dado cuts (dado blade sets), and even cutting non-wood materials like plastics or thin aluminum.

Factors to Consider When Choosing blade

Prioritize dedicated blades for the majority of your material cuts. Consider the following when making a blade selection

Rip Blades:

10-30 teeth with FTG grind for efficient, smooth rip cuts

Aggressive hook angles for rapid cutting with the grain

Wide gullets for clearing sawdust

Cross-cut Blades:

60-100 teeth with ATB grind minimize tear-out across the grain

Less aggressive hook angle for controlled cuts

Ideal for sheet goods like plywood and melamine

General Purpose Blades:

Around 40 teeth prioritize clean cross-cuts, with moderate performance for rip cuts

In the mean time, you should consider the material Hardness, the harder materials may necessitate carbide-tipped blades. For high-end work, select blades with higher tooth counts and tailored grinds will give you better result. Conclusion: Understanding table saw blade design and the terminology will empower you to make informed decisions for various woodworking projects. Experimentation is key! Remember, the "best" blade depends entirely on your specific needs and priorities. Refer to the Rockler Saw Blades 101 article for a solid foundation and additional insights.