Exploring Safety Features in Modern Table Saws

The evolution of table saw technology has not only enhanced cutting precision but has also revolutionized safety features. Modern table saws come equipped with a range of advanced safety features designed to protect users and prevent accidents.

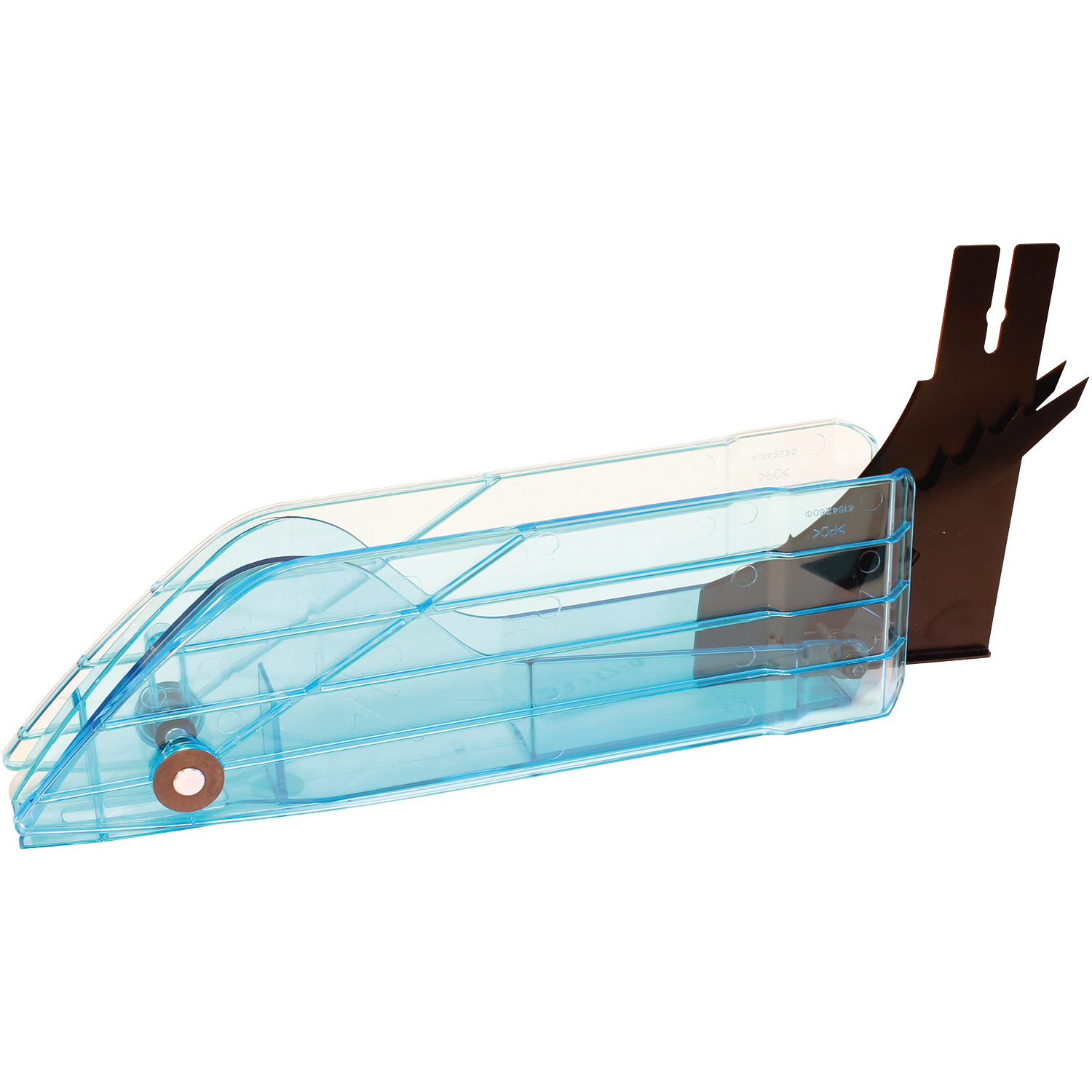

Table saw blade guard serves as one of the most important safety features that physically block the user accidently touch the spinning blade during operation.It’s typically made of clear plastic. Generally it works by covering the blade when it’s not in contact with the workpiece, reducing the chance of accidental contact with the blade. When making a cut, the guard lifts up, allowing the workpiece to pass through, and then falls back into place once the cut is complete.

Table saw blade guards are available in two primary types:

- Traditional-style Guards: Mounted on the trunnion assembly of the saw, these guards often include additional features such as splitters, spreaders/riving knives, and anti-kickback fingers. These features collectively contribute to reducing the likelihood of the saw blade propelling the workpiece back towards the operator.

- Over-arm Guards: Installed on the extension table, these guards offer easier adjustability and may include a dust collection system. However, they typically lack anti-kickback devices

A riving knife is another crucial safety feature found on almost all modern table saws. It’s a flat piece of metal, mounted behind the saw blade and moves up and down with the blade as you adjust its height.

The primary purpose of a riving knife is to prevent workpiece kickback, which is one of the most dangerous hazards associated with using a table saw. Kickback occurs when the workpiece gets caught on the back of the blade and is propelled back towards the operator. This can happen if the kerf (the cut made by the saw) closes up and pinches the blade.

The riving knife works by keeping the two halves of a freshly cut board separated as it is pushed through the blade. This prevents the kerf from closing up and pinching the blade, thus reducing the chance of kickback. The riving knife is designed to “hug” the blade no matter what position it is in. Unlike a splitter, which must be removed from the saw for crosscutting, a riving knife can remain in place for crosscuts and any type of cut where the saw kerf runs entirely through the thickness of the board.

The Anti-Kickback Pawl consists of small, tooth-like projections that engage with the surface of the wood as it moves through the blade. These pawls allow the wood to move in one direction (towards the front of the saw) while preventing backward movement. In the event of kickback, the pawls dig into the wood and help prevent it from being forcefully thrown back at the operator.

Key features of Anti-Kickback Pawls include:

- Engagement: The pawls engage with the wood, offering resistance against backward movement while allowing it to move forward.

- Adjustability: Many table saws allow users to adjust the height and positioning of the Anti-Kickback Pawls to accommodate different thicknesses of material.

- Compatibility: Anti-Kickback Pawls are typically designed to work in conjunction with other safety features such as blade guards and riving knives.

- Removability: In some cases, Anti-Kickback Pawls can be easily removed or disengaged, allowing users flexibility for certain types of cuts or woodworking tasks.

A splitter is basically a small vertical blade made of metal or sometimes, plastic, which holds the kerf open behind the table saw blade. Unlike the riving knife, the splitter is fixed in place and does not move with the blade during the height adjustments. If the application requests some special cut , such as dado cuts , angle cut or some no-through cut, the splitter has to be removed.

- Magnetic switche function ensure that power is cut off in the event of a power outage, which preventing unexpected restarts.

- Emergency shut-off switches are easily accessible, allowing users to quickly power down the saw in case of an emergency.

SawStop is a notable brand known for incorporating advanced safety features into their table saws. They have a safety system that includes a smart sensor to detect contact with skin and trigger an immediate brake response, preventing serious injuries. But accourding to the comany, the SawStop system has restrictions such as deactivation for cutting wet timber, limitations on blade types, and requirements for specific kerf sizes, making retrofitting impractical and cautioning that activating the braking system may lead to blade damage. These considerations underscore the importance of adhering to guidelines for optimal safety and functionality.

Many contemporary table saws come with integrated dust collection systems to keep the workspace clean. A clean workspace not only enhances visibility but also reduces the risk of accidents caused by debris.